Rubber Bushing

With over 40 years of experience in the rubber industry, Zong Yih Rubber specializes in rubber-to-metal bonding technology and precision vibration-control components.

Our Rubber Bushings (Full Bonded Type) are one of our core and highly reliable product lines for industrial and automotive applications.

Our rubber isolator bushings integrate rubber and metal sleeves through a stable, high-strength bonding process, providing excellent vibration damping, structural support, noise reduction, and durability under dynamic loads.

Standard Specifications

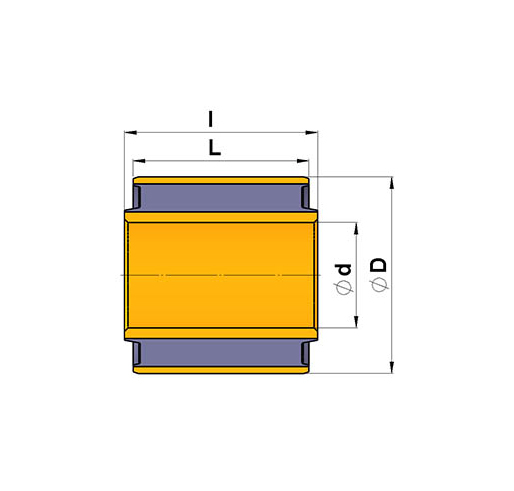

Rubber Bushing (Full Bonded)

- Elastomer: Natural Rubber (NR)

- Hardness: 55–75 Shore A (adjustable per application)

- Metal Component: Zinc-plated Steel

Features & Functions

- Vibration Absorption

The rubber effectively absorbs vibration and impact energy, reducing vibration transmission during operation and improving system stability. - Noise Reduction

The rubber layer isolates direct metal-to-metal contact, significantly reducing noise and improving operating quality. - Elastic Support & Cushioning

Capable of handling compressive, shear, and torsional loads, the bushing ensures proper elasticity and buffering during dynamic movement. - Enhanced Durability

The full-bonded design provides long-term resistance to repeated loads, preventing debonding and deterioration, making it suitable for high-frequency and high-vibration applications.

How Rubber Bushings Work

A rubber bushing functions as a vibration isolator that absorbs energy through elastic deformation.

When compressive or shear forces are applied, the elastomer deforms and disperses the energy across the bonded interface. This prevents excessive vibration transmission between connected metal components.

The full-bonded rubber-to-metal design enhances stiffness control, energy absorption, and stability, making it ideal for:

- Suspension systems

- Powertrain vibration isolation

- Machinery rotating parts

- Structural damping applications

This combination of elasticity and bonding strength significantly reduces noise, increases system precision, and prolongs equipment lifespan.

Application

Rubber Bushing Applications

- Automotive & Transportation

Suspension systems, control arm bushings, engine mounts, steering mechanisms, stabilizer link connections, and other vibration-control components. - Industrial Machinery

Power transmission systems, pumps, compressors, industrial motors, linkages, rotating mechanisms, vibration isolation bases, and more. -

Home Appliances & Power Tools

Compressor mounts, motor vibration isolation, and damping interfaces for handheld tools. - Agricultural & Construction Equipment

Connection points and support structures in high-vibration, heavy-load mechanical systems.

Why Choose Zong Yih Rubber as Rubber Buffer Manufacturer

- Strong Rubber Compound Development Capability

Formulations can be adjusted for hardness, tensile strength, tear resistance, oil resistance, heat resistance, and fatigue performance. - Precision Molds & Full Bonding Technology

Ensures strong rubber-to-metal adhesion, enhancing product reliability and service life. - Strict Quality Management

ISO 9001 and IATF 16949 certified, ensuring stable and consistent product quality.

Contact Us

Zong Yih Rubber provides customized development, compound consultation, and technical support.

For more product information or quotations, contact us today — we can help you design the ideal vibration-control solution for your system!

Specifications (Metric mm)

Specifications

| 變體 | PBB2001 |

| P/N | PBF0143 |

| D | 16+0.1 |

| d | 8+0.15 |

| I | 17+/-0.1 |

| L | 15+/-0.2 |

| Perm.radial Force Fr N | 300 |

| Radial Spring Rate Cr N/mm² | 2960 |

| Perm.axial Force Fa N | 60 |

| Radial Spring Rate Ca N/mm² | 320 |

| Perm.torsion Angle Degrees ° | 15 |

| Perm. Static Torque Md Nm | 3.75 |

| Torsion Spring Rate Cf Nm/° | 0.25 |

| Max. Torsion Angle Degrees ° | 30 |

| Max. Slip Torque Md Nm | 7.5 |