Quality inspection equipment

At ZONG YIH, material test instruments such as Tensile Strength instrument, 2.5D Digital Profile Projector, Rheometer Device, High/Low temp. resistance test, Ozone resistance, Heating Aging test, Compression Set, Fluid Resistance test, and Dynamic Test Device available ensures compliance with ASTM, DIN norm or your unique applications.

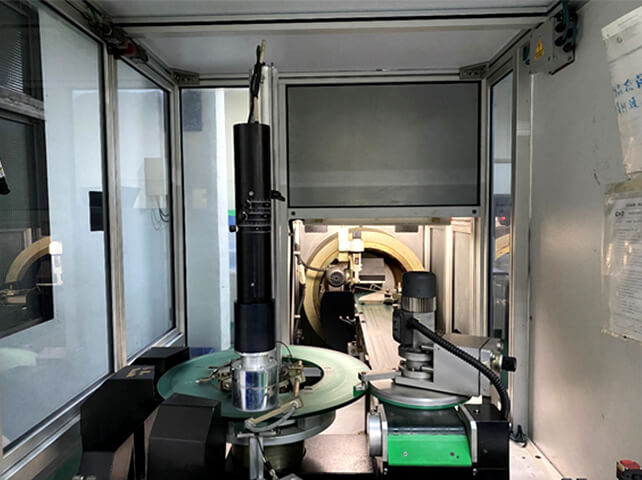

Automatic Quality Inspection Machines

- Automated Inspection Machine

- Applicable for round shape products with dia. below 34mm & thickness below 10mm.

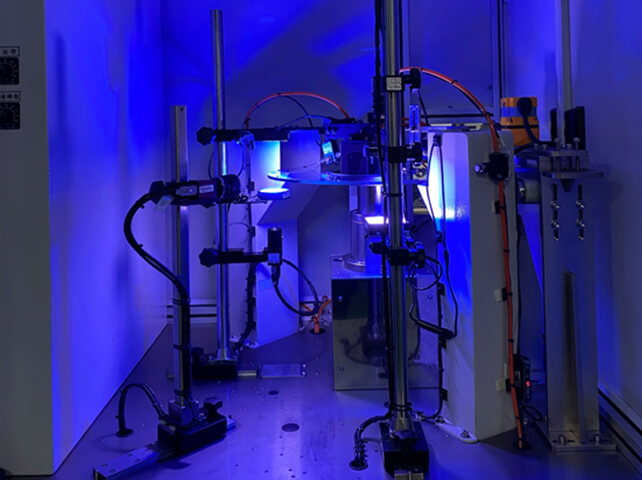

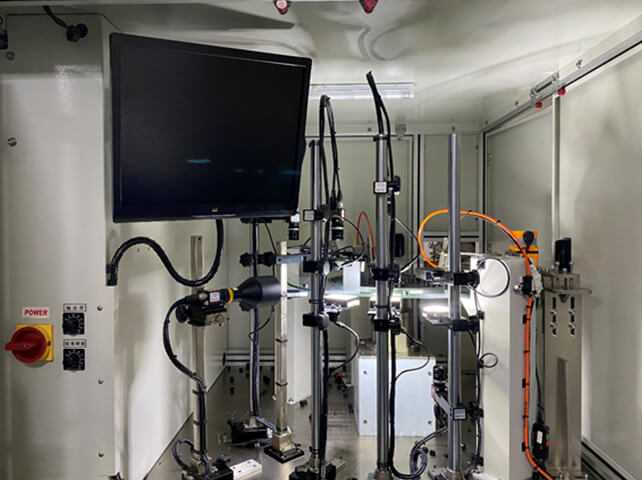

- Double Glass Optical Screening Machine

- Applicable to the inspection of gasket products.

- Double Glass Optical Screening Machine (3CCD)

- Appearance and burrs are detected at the upper and lower parts, and the height can be checked (not measured).

- Double Glass Optical Screening Machine (5CCD)

- Appearance and burrs of the upper three places and the next place can be inspected, and the height can be checked (not measured).

- DossZehn Optical Quality Inspection Machine

- 5 to 80mm in diameter and 15mm in thickness or less circular surface appearance and burr measurement.

- Inner parting line of the O-ring within a certain line diameter and specific irregular products can be inspected.

Measuring and Testing Instruments

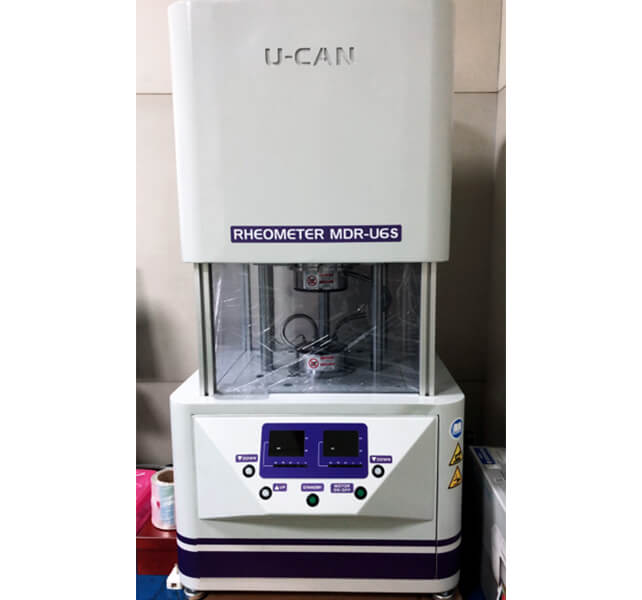

- Rotorless Rheometer

- All rubber compounds are applicable.

- Test the vulcanization curve and various vulcanization data of the rubber material as the basis for the acceptance of the rubber material and reference for the manufacturing process.

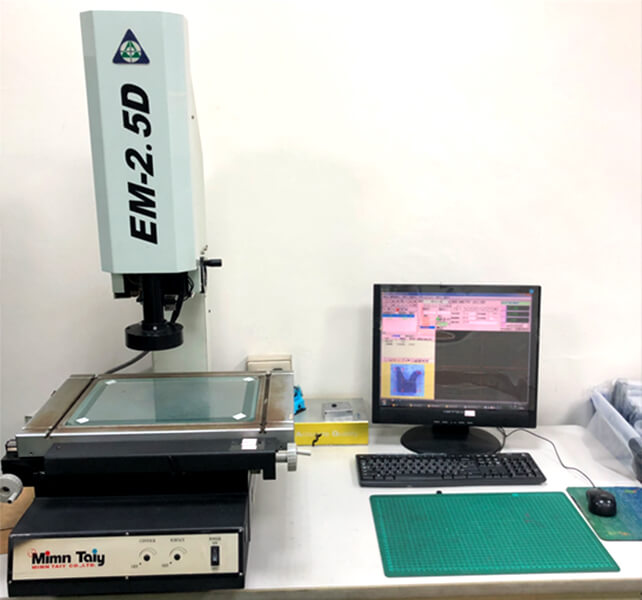

- 2.5D image measuring instrument

- Length: 270mm Width: 180mm Height: Rubber products, semi-finished products, metal accessories, etc. measured within 80mm.

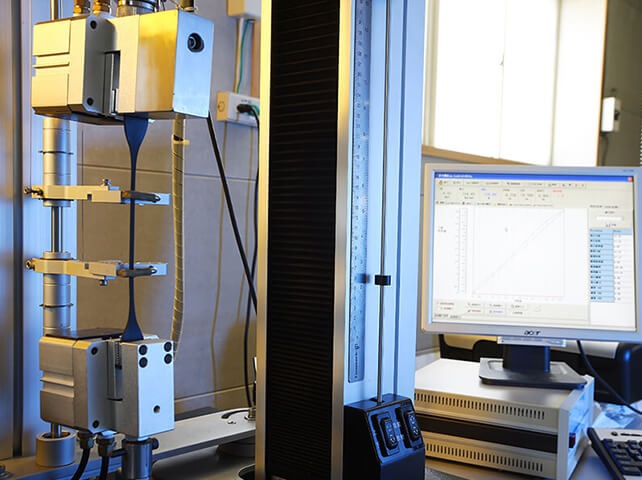

- Material testing machine

- Rubber material tensile strength, elongation, finished product static stiffness and destructive force testing.

- Loading: 250kg / 1000kg

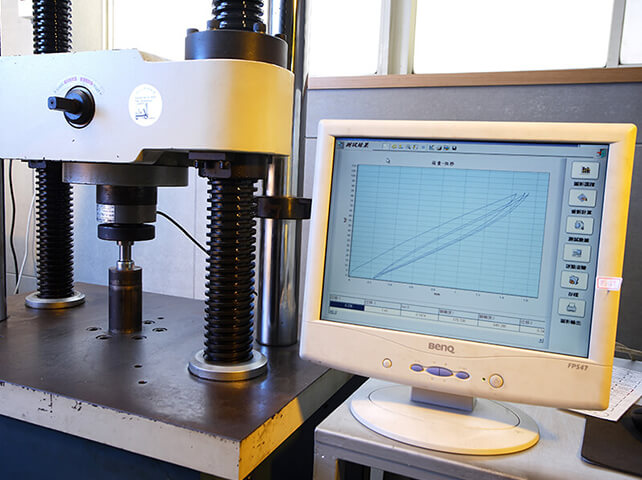

- Hydraulic universal testing machine

- Rubber material, static stiffness and destructive force of the finished product testing.

- Loading: Max 30000kg

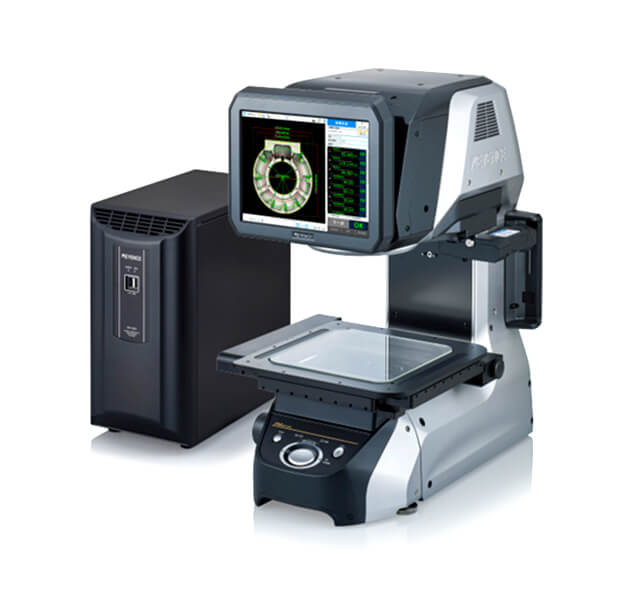

- IM Image Size Measuring Instrument

- Quick measurement the size of rubber products, semi-finished products, metal accessories, etc., to avoid human error.

- Manual inspection

- Manual quality inspection operations, delicate and focused, insist on giving customers the best quality.