Rubber Bushing

Rubber Bushing Manufacturer & Suppliers – Vibration Isolation Solutions

With over 20e as a trusted rubber bushing manufacturer and supplier, ZONG YIH is ISO 9001 certified and supplies products to OEM clian, and North America. We specialize in the production of rubber isolator bushings designed for industrial and automotiv systems. Our rubber bushings are engineered to absorb shock, reduce noise, and extend equi

What Is a Rubber Bushing Used For?

- Improved Safety and Comfort – Used in automotive suspension and steering systems for smoother operation.

- Vibration and Noise Reduction – Prevent damage from repetitive shock and improve machinery lifespan.

- Long-Term Performance – Designed for maintenance-free use and optimized stiffness in all directions.

Our rubber bushings are widely used in the automotive industry (vehicles, motorcycles, railway systems), heavy equipment, and industrial machinery. Whether for OEM rubber bushing parts or replacement needs, we provide both standard and custom designs for your specific application.

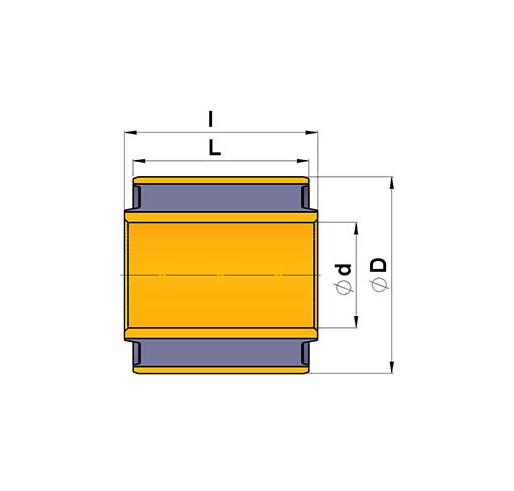

Our Rubber Isolator Bushing Specifications

-Material: NR (Natural Rubber)

-Hardness Options: 50 / 60 / 70 Shore A

-Temperature Range: -40°C to 80°C (up to 100°C instant)

-Functions: Shockproof, Noise Reduction, Component Protection

ZONG YIH provides high-quality rubber isolator bushings and other custom rubber parts backed by years of engineering experience. With in-house manufacturing and strict quality control, we ensure durable, reliable components for global clients. Contact ZONG YIH – your trusted rubber bushing manufacturer from Taiwan.

| No. | P/N | d | D | I | L | Perm.radial force Fr N |

Radial spring rate Cr N/mm² |

Perm.axial force Fa N |

Radial spring rate Ca N/mm² |

Perm.torsion angle degrees ° |

Perm. Static torque Md Nm |

Torsion spring rate Cf Nm/° |

Max. torsion angle degrees ° |

Max. Slip torque Md Nm |

INQUIRY |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PBF0143 | 8+0.15 | 16+0.1 | 17+/-0.1 | 15+/-0.2 | 300 | 2960 | 60 | 320 | 15 | 3.75 | 0.25 | 30 | 7.5 | ||

| PBF0144 | 8+0.15 | 20+0.1 | 17+/-0.1 | 15+/-0.2 | 300 | 1650 | 60 | 230 | 15 | 3 | 0.2 | 30 | 6 | ||

| PBF0148 | 8+0.15 | 22+0.1 | 16+/-0.1 | 10+/-0.2 | 100 | 570 | 140 | 109 | 13 | 1.56 | 0.12 | 26 | 3.12 | ||

| PBF0145 | 10+0.15 | 18+0.1 | 20+/-0.1 | 18+/-0.3 | 300 | 3400 | 80 | 480 | 15 | 6.15 | 0.41 | 30 | 12.3 | ||

| PBF0146 | 10+0.15 | 22+0.1 | 33+/-0.1 | 30+/-0.3 | 2800 | 5890 | 410 | 540 | 15 | 10.8 | 0.72 | 30 | 21.6 | ||

| PBF0147 | 10+0.15 | 24+0.1 | 17+/-0.1 | 14+/-0.2 | 200 | 1400 | 160 | 200 | 15 | 3.75 | 0.25 | 30 | 7.5 | ||

| PBB2005 | 10+0.15 | 25+0.1 | 24+/-0.1 | 20+/-0.3 | 4000 | 2060 | 410 | 220 | 15 | 5.1 | 0.34 | 30 | 10.2 | ||

| PBF0107 | 10+0.15 | 26.6+/-0.1 | 45+/-0.1 | 20+/-0.3 | - | - | - | - | - | - | - | - | - | ||

| PBB2006 | 12+0.15 | 24+0.1 | 38+/-0.1 | 35+/-0.3 | 3000 | 6100 | 1330 | 550 | 10 | 10.6 | 1.06 | 20 | 21.2 | ||

| PBB2007 | 12+0.15 | 25+0.1 | 28+/-0.1 | 25+/-0.3 | 4900 | 4070 | 500 | 415 | 10 | 7.9 | 0.79 | 20 | 15.8 | ||

| PBF0138 | 12+0.15 | 26+0.1 | 24+/-0.1 | 18+/-0.3 | 690 | 2220 | 680 | 252 | 13 | 6.63 | 0.51 | 26 | 13.26 | ||

| PBB2008 | 12+0.15 | 26+0.1 | 36+/-0.1 | 32+/-0.3 | 1370 | 3960 | 840 | 515 | 13 | 12.61 | 0.97 | 26 | 25.22 | ||

| PBF0130 | 13+0.15 | 30+0.1 | 40+/-0.1 | 40+/-0.3 | 1670 | 3625 | 2310 | 450 | 15 | 14.85 | 0.99 | 30 | 29.7 | ||

| PBB2009 | 14+0.15 | 30+0.1 | 76+/-0.1 | 67+/-0.3 | 3900 | 5200 | 2310 | 780 | 15 | 28.5 | 1.9 | 30 | 57 | ||

| PBB2010 | 16+0.2 | 32+0.15 | 17+/-0.1 | 16+/-0.3 | 1900 | 1580 | 310 | 250 | 12.5 | 8.88 | 0.71 | 25 | 17.75 | ||

| PBB2011 | 16+0.2 | 32+0.15 | 28+/-0.1 | 25+/-0.3 | 3600 | 4560 | 770 | 380 | 15 | 6.5 | 1.1 | 30 | 33 | ||

| PBB2012 | 16+0.2 | 32+0.15 | 54+/-0.1 | 50+/-0.3 | 3900 | 4900 | 1230 | 590 | 7.5 | 13.88 | 1.85 | 15 | 27.75 | ||

| PBB2013 | 16+0.2 | 40+0.15 | 38+/-0.1 | 32+/-0.3 | 1600 | 1800 | 320 | 350 | 15 | 16.2 | 1.08 | 30 | 32.4 | ||

| PBF0139 | 18+0.3 | 34+0.15 | 36+/-0.1 | 32+/-0.3 | 1570 | 4180 | 830 | 530 | 14 | 23.52 | 1.68 | 28 | 47.04 | ||

| PBF0131 | 20+0.3 | 45+0.15 | 62.5+/-0.2 | 55+/-0.3 | 3430 | 5435 | 1860 | 585 | 15 | 44.55 | 2.97 | 30 | 89.1 | ||

| PBF0132 | 20+0.3 | 45+0.15 | 62.5+/-0.2 | 59.5+/-0.3 | 3900 | 4820 | 910 | 530 | 15 | 37.95 | 2.53 | 30 | 75.9 | ||

| PBB2014 | 24+0.3 | 42+0.15 | 96+/-0.2 | 90+/-0.3 | 3900 | 8460 | 5040 | 1744 | 5 | 54.65 | 10.93 | 10 | 109.3 | ||

| PBF0133 | 25+0.3 | 50+0.15 | 67.5+/-0.2 | 65.5+/-0.3 | 6380 | 9800 | 760 | 975 | 15 | 84 | 5.6 | 30 | 168 | ||

| PBF0134 | 25+0.3 | 55+0.15 | 93.5+/-0.2 | 89.5+/-0.3 | 9800 | 10350 | 1650 | 1015 | 10 | 83.3 | 8.33 | 20 | 166.6 | ||

| PBB2015 | 26+0.3 | 40+0.15 | 45+/-0.1 | 40+/-0.3 | 4900 | 7830 | 2550 | 940 | 7 | 38.22 | 5.46 | 14 | 76.44 | ||

| PBF0135 | 30+0.3 | 55+0.15 | 94+/-0.2 | 89.5+/-0.3 | 13700 | 17460 | 2600 | 1490 | 10 | 131.3 | 13.13 | 20 | 262.6 | ||

| PBB2016 | 30+0.3 | 56+0.15 | 55+/-0.2 | 50+/-0.3 | 15000 | 7660 | 1300 | 905 | 12.5 | 87.63 | 7.01 | 25 | 175.25 | ||

| PBF0137 | 40+0.3 | 75+0.2 | 70+/-0.2 | 57+/-0.3 | 5900 | 6910 | 4510 | 880 | 14 | 210 | 15 | 28 | 420 | ||

| PBF0136 | 50+0.3 | 70+0.15 | 60+/-0.2 | 60+/-0.3 | 11700 | 15970 | 2940 | 2020 | 3 | 50.9 | 50.3 | 6 | 301.8 | ||

| PBB2017 | 50+0.3 | 80+0.2 | 100+/-0.2 | 95+/-0.3 | 14700 | 14960 | 3430 | 1740 | 8 | 150.4 | 18.8 | 16 | 300.8 |

Industrial Rubber Bushing FAQ

Q: What is a rubber bushing?

Industrial rubber bushings, also known as rubber bushes, are vibration isolators used as buffers between two mechanical parts. They absorb energy, reduce impact and noise, and allow limited movement, protecting surrounding components and improving system performance.

Q: Do you offer custom rubber bushings?

Yes. As a professional rubber bushing manufacturer, ZONG YIH provides both standard and custom rubber bushing solutions tailored to your application needs, including material selection, hardness, and size.

Q: How can I choose the right rubber bushing for my application?

Choosing the right rubber bushing depends on the operating conditions such as load, movement, temperature, and required stiffness. Our engineering team can assist you and recommend the best bushing for your system.

Q: Where is ZONG YIH located, and do you ship internationally?

ZONG YIH is a rubber bushing manufacturer based in Taiwan. We provide global delivery services and support international clients with fast lead times and reliable logistics.

Q: What’s the difference between a rubber bushing and a metal bushing?

Rubber bushings are flexible and effective at absorbing vibrations, making them ideal for vibration damping in dynamic systems.

In contrast, metal bushings are rigid and highly wear-resistant, suitable for applications requiring durability and precision.